Dirt Cut Fill Calculator

Free Excavation & Grading Estimator for Balanced Cut/Fill Projects

Pro Fill Dirt Calculator

Accurate estimates for Yards, Tons, & Compaction

Results

How to Calculate for Dirt Cut Fill Calculator

The Formula

Calculate cut and fill volumes separately. Apply bulking factors (10-60%) for cut material. Apply compaction factors (10-25%) for fill material. Balance grades to reuse cut as fill and minimize costs.

Measure Accurately

Measure in feet. For depth, measure in inches and our tool handles the conversion (divide by 12).

Check Your Shape

Most dirt cut-fill-calculator projects are rectangles. If irregular, break it into smaller shapes.

Add Compaction

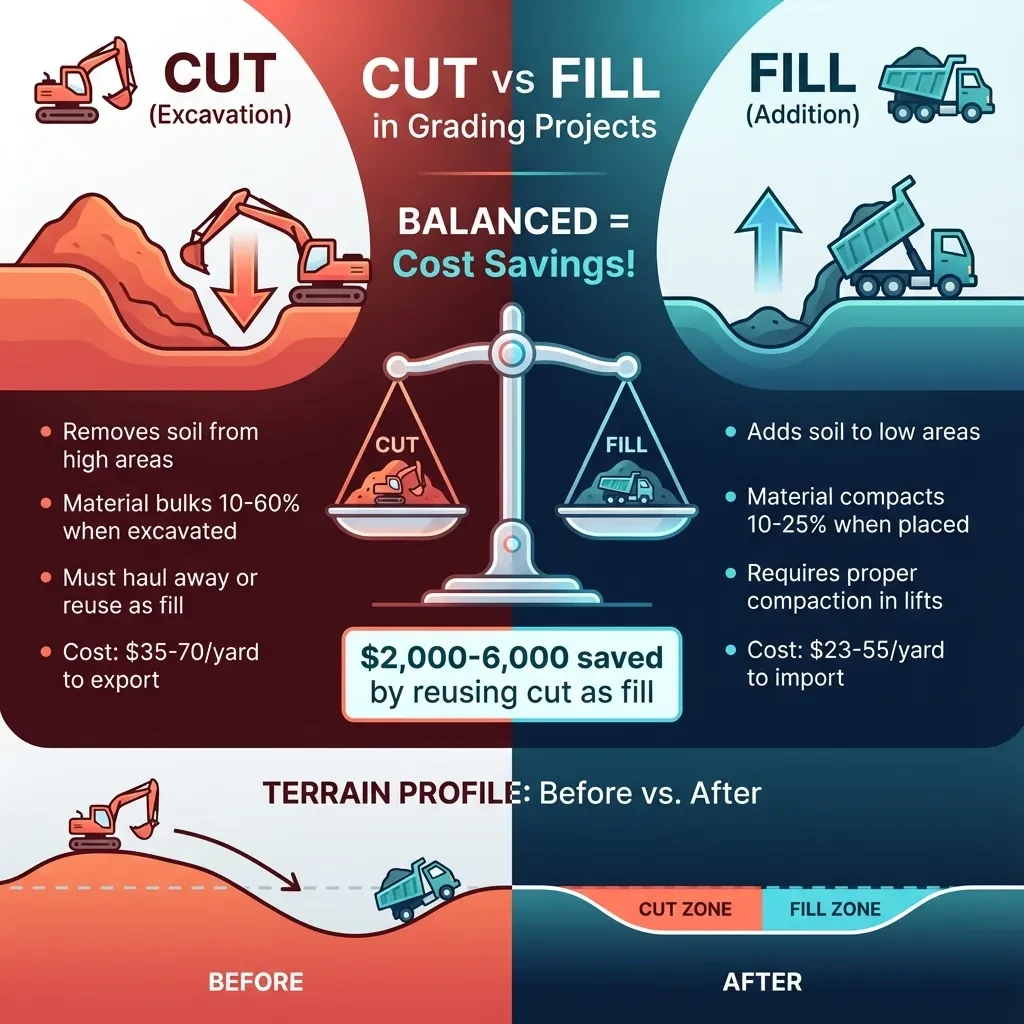

Balancing cut and fill saves $2,000-6,000 on typical projects by eliminating import/export costs. Soil volume changes (bulking 10-60%, compaction 10-25%) affect material quantities significantly. Proper calculations prevent ordering mistakes costing thousands.

What Is Cut and Fill in Grading?

Cut (Excavation) Explained

Cut refers to removing soil from higher areas to lower the elevation and achieve your desired grade. When you excavate a hillside to create a level building pad or dig out a high spot in your yard, you're performing a cut operation. The excavated material either gets hauled away to a disposal site or reused elsewhere on your property as fill.

Understanding cut operations matters because excavated soil undergoes bulking. When you remove compacted soil from the ground, it expands by 10-60% depending on soil type. A cubic yard of dense clay in the ground becomes 1.25 to 1.35 cubic yards of loose material in your dump truck. This bulking affects how many truckloads you need for removal and influences disposal costs significantly.

Fill (Adding Soil) Explained

Fill involves adding soil to low areas to raise the elevation to your target grade. When you bring in dirt to level a depression in your yard or build up a foundation area, you're creating fill. This material gets placed in layers called lifts and compacted with heavy equipment to achieve stability.

Fill presents the opposite challenge from cut. When you place loose fill dirt and compact it properly, the material compresses by 10-25% depending on soil type and compaction effort. If you need one cubic yard of compacted fill in place, you must order 1.15 to 1.25 cubic yards of loose material to account for this volume reduction during compaction.

Why Balancing Cut and Fill Saves Money

The most important concept in cut and fill grading is achieving balance. When your project requires both cutting and filling, reusing the cut material as fill eliminates import and export costs entirely. Consider a typical scenario: cutting 80 cubic yards from a high area and filling 75 cubic yards in a low area. If you export all 80 yards and import 75 yards separately, you pay removal fees ($35-70 per yard) and delivery fees ($23-55 per yard). Total cost ranges from $4,525 to $10,025.

Alternatively, if you balance the grades by adjusting the target elevation slightly, you might achieve 77 yards cut and 74 yards fill. Now you reuse 74 yards of cut as fill on-site and only export 3 yards excess. Your costs drop to $105-210, saving $4,315 to $9,815. Even adjusting your proposed grade by just 4-6 inches can swing the balance from 35 yards excess cut to nearly balanced, saving $1,200 to $2,400.

Cut and Fill Calculation Methods

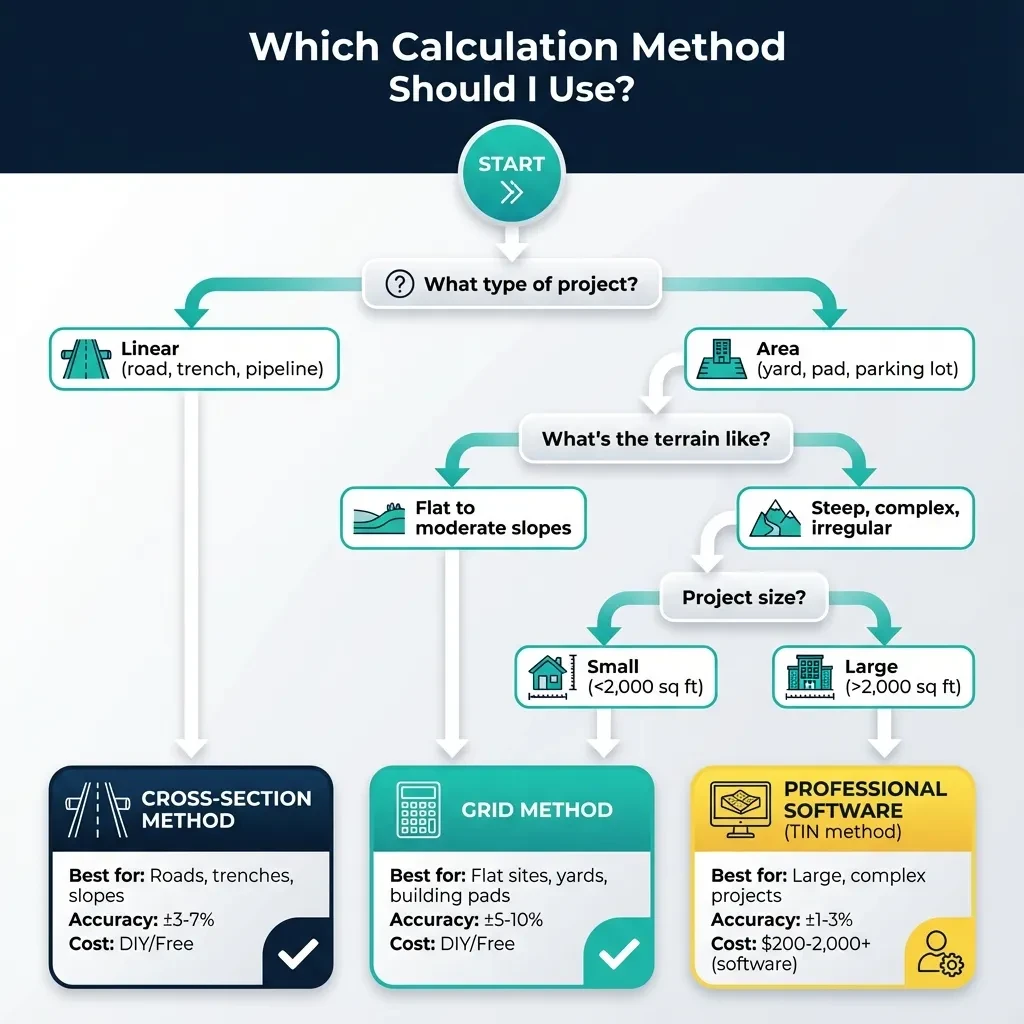

Grid Method (Best for Flat/Moderate Terrain)

The grid method works by overlaying a regular grid pattern on your site plan and measuring elevations at each grid intersection. For a 60×40-foot building pad, a 10×10-foot grid creates 7 longitudinal lines and 5 transverse lines, totaling 35 grid points. At each intersection, survey the existing ground elevation and determine the proposed finished elevation.

Calculate the cut or fill depth at each point by subtracting proposed from existing elevation. Positive values indicate cut while negative values show fill. Multiply each cell area (100 square feet for 10×10 grids) by the average cut or fill depth from its four corner points to get cell volume. The grid method excels for building pads, parking lots, and yards, providing ±5-10% accuracy for preliminary planning.

Cross-Section Method (Best for Linear Projects)

Cross-section calculations work perfectly for linear projects like roads, driveways, trenches, and pipelines. Divide the project length into equal intervals, typically 20-50 feet depending on terrain complexity. At each station, survey a cross-section perpendicular to the centerline showing existing and proposed ground profiles.

Calculate the area between existing and proposed grades for each cross-section, then find volume between sections as the average of their areas multiplied by distance. This method provides excellent accuracy (±3-7%) for linear projects and handles significant slope changes better than grid methods.

TIN Method (Professional Software)

Professional civil engineering software like Civil 3D and Kubla Cubed uses triangulated irregular networks (TIN) to create highly accurate digital terrain models. The software triangulates both existing and proposed surfaces into networks of connected triangles, then calculates the volume of triangular prisms formed between corresponding triangles. This method handles complex terrain with exceptional accuracy (±1-3%) but requires significant software investment ($200-2,000+) and learning curve.

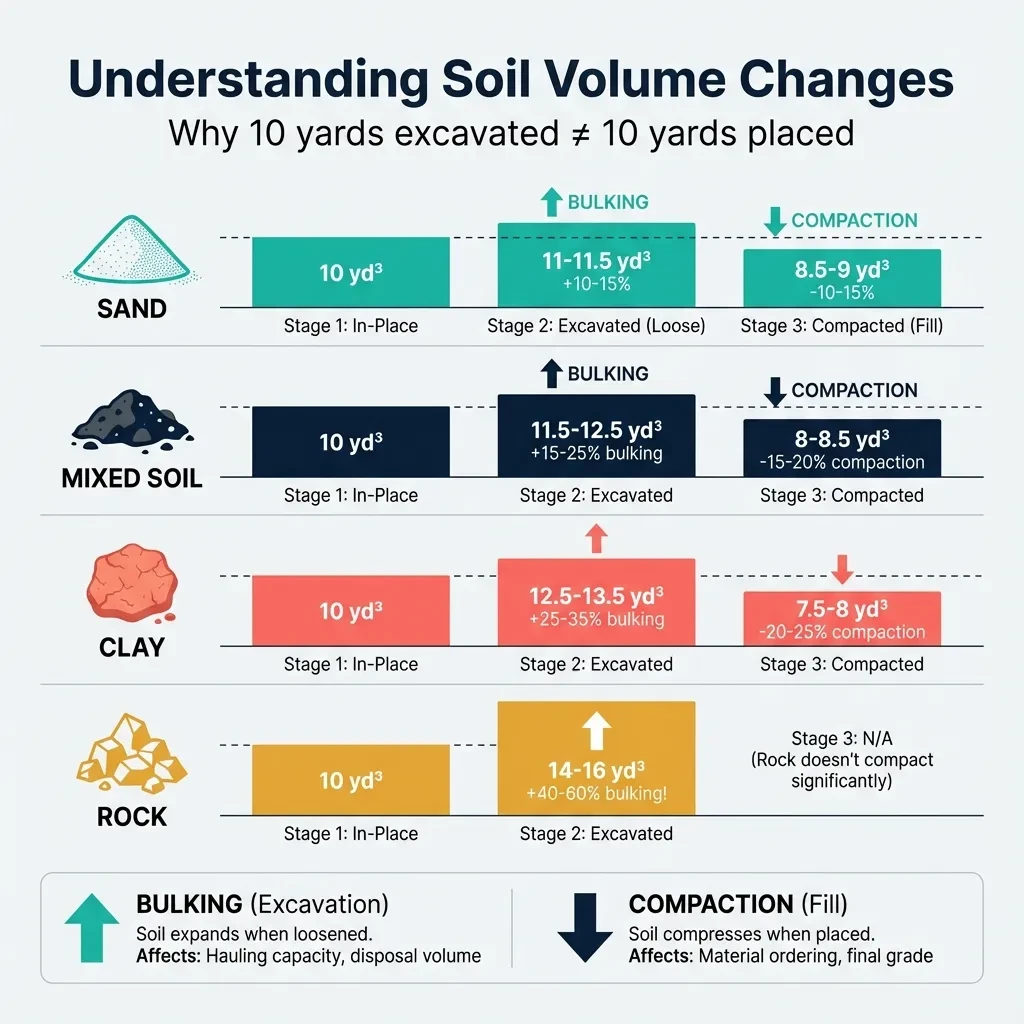

Understanding Soil Volume Changes

Bulking Factor (Excavation)

Soil bulking describes the volume increase that occurs when you excavate compacted in-place material. Natural soil sits under its own weight and geological forces over thousands of years. Excavation breaks apart soil particles, introduces air voids, and reduces density significantly.

Sandy soils exhibit the least bulking at 10-15%. Mixed soils combining sand, silt, and clay bulk 15-25%. Clay soils show dramatic bulking at 25-35%. Rock presents the extreme case with 40-60% bulking. Always apply bulking factors when calculating removal costs and truck capacity needs.

Compaction Factor (Fill)

Compaction removes air voids from loose fill material through mechanical compression using rollers and compactors, increasing density and reducing volume. Topsoil compacts 10-15%, common fill compacts 15-20%, and structural fill compacts 20-25% when achieving code-required 90-95% density.

Calculate fill material orders by dividing your required compacted volume by the compaction fraction. For 22% compaction loss, divide by 0.78. Proper compaction requires placing material in 6-8 inch lifts, making 4-6 passes with appropriate equipment, and verifying density through field testing.

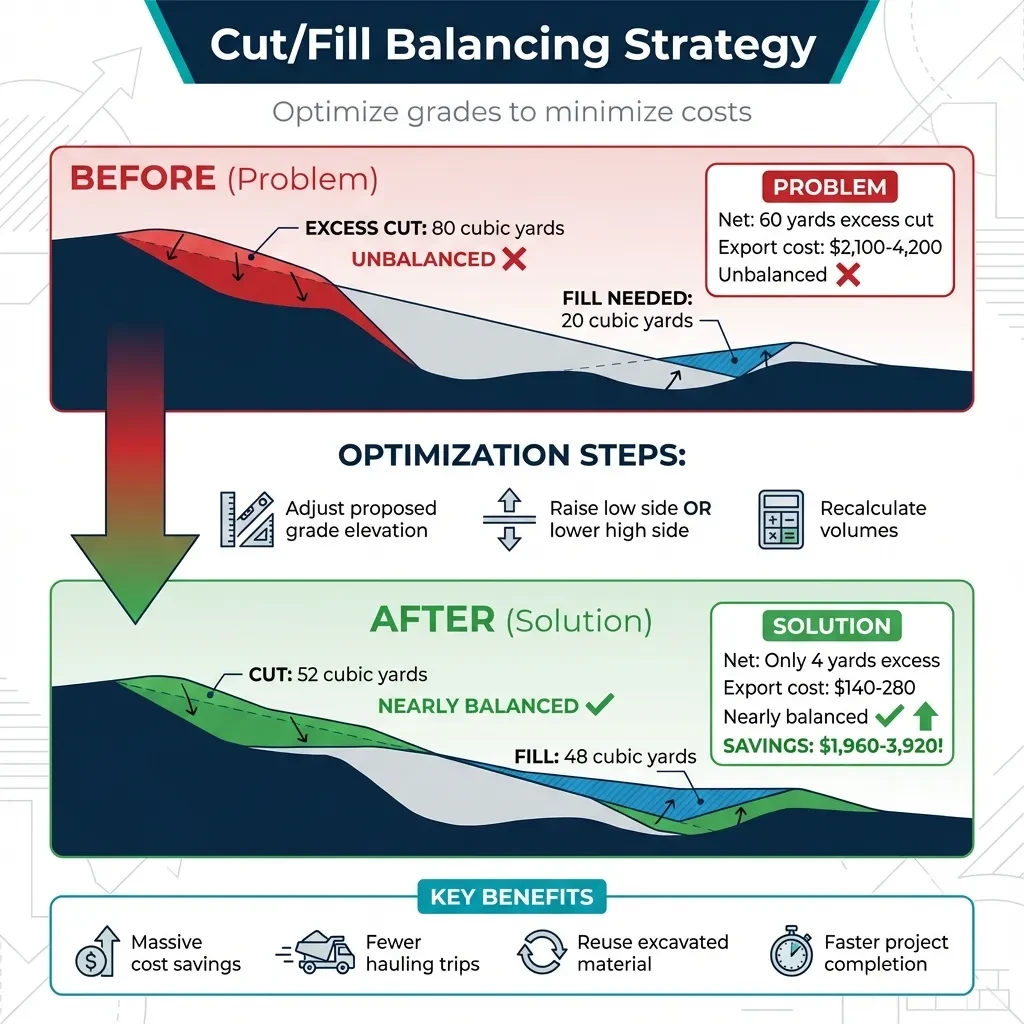

How to Balance Cut and Fill to Minimize Costs

Why Balancing Matters

Export costs combine disposal fees ($20-40 per cubic yard) with trucking charges ($15-30 per yard), totaling $35-70 per yard. Import costs include material purchase ($8-25 per yard) plus delivery ($15-30 per yard), totaling $23-55 per yard. Balancing eliminates these costs by reusing cut material as fill on-site.

Strategies to Achieve Balance

The most powerful balancing tool is adjusting target grade elevation. Raising the proposed grade by even a few inches reduces cut requirements while increasing fill needs, moving both toward balance. For a 2,400 square foot pad with 40 yards excess cut, raising finished grade 4 inches reduces cut by approximately 30 cubic yards, saving $1,050 to $2,100.

Redistribute material during construction by stockpiling cut for later use as fill. Modify design elements where possible: move building pads toward natural high points, adjust driveway alignment to follow contours, and create gentle berms that consume excess cut without requiring export.

Complete Cost Breakdown

Material and Hauling Costs

Topsoil runs $15-35 per cubic yard, common fill dirt costs $8-18 per yard, structural fill ranges $12-25 per yard, and gravel base costs $18-35 per yard. Hauling charges depend on distance: short hauls under 5 miles average $15-20 per yard, moderate distances of 10-15 miles run $20-30 per yard, and long hauls exceeding 20 miles reach $30-45 per yard.

Equipment and Labor Costs

Mini excavators rent for $200-350 per day, mid-size excavators cost $300-500 daily, bulldozers range $300-700 per day, and compaction equipment runs $75-400 per day. Heavy equipment operators command $50-100 per hour while general labor runs $25-50 per hour.

Project Cost Examples

Small projects like 50-foot driveways with 10 cubic yards cost $1,000-1,400 total. Medium projects such as 60×40-foot building pads requiring 50 yards cost $3,400-4,200. Large projects like 100×100-foot yard grading moving 120 yards run $8,900-11,000.

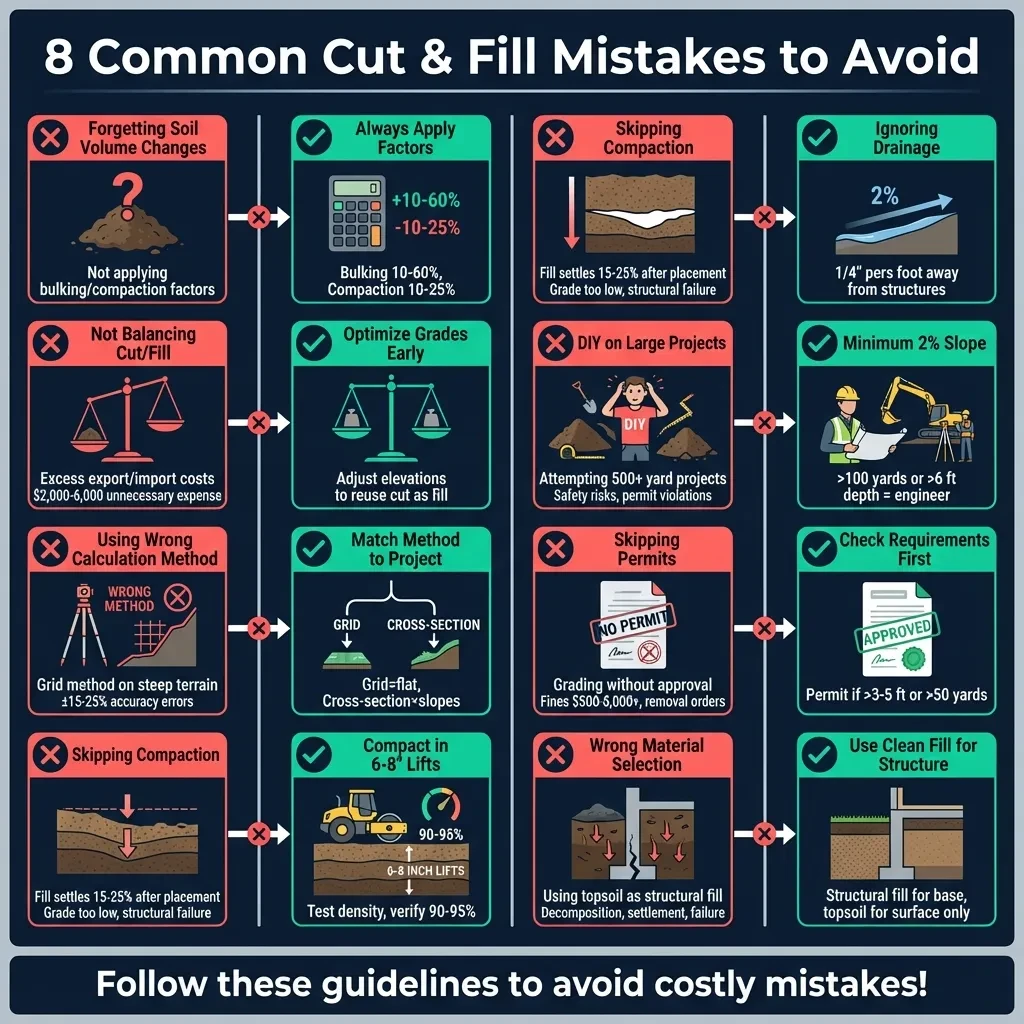

Common Mistakes to Avoid

Forgetting soil volume changes leads to underestimating removal needs (bulking) or ordering insufficient fill (compaction). Not balancing cut and fill results in $2,000-6,000 unnecessary export/import costs easily avoided through grade adjustment. Using wrong calculation methods creates ±15-25% errors. Skipping compaction causes 15-25% settlement and structural failure.

Ignoring drainage creates water pooling and erosion. DIY on large complex projects creates safety risks and code violations. Skipping permits leads to stop-work orders and $500-5,000+ fines. Wrong material selection using topsoil as structural fill causes decomposition and settlement over 2-5 years.

When to Hire a Professional

DIY-Appropriate Projects

Small straightforward projects under 20 cubic yards suit experienced DIYers comfortable operating equipment safely. Simple rectangular shapes on relatively flat terrain with depths under 2-3 feet minimize safety risks. Non-critical applications like garden beds and landscaping berms tolerate minor imperfections.

Hire Contractor (No Engineering Required)

Medium projects from 20-100 cubic yards benefit from contractor expertise and efficiency. Moderate complexity including irregular boundaries or varying depths exceeds casual DIY capabilities. Permitted work not requiring engineering still demands professional quality to pass inspections.

Require Professional Engineering

Large projects exceeding 100-150 cubic yards warrant engineering analysis. Deep cuts or fills exceeding 6 feet must be engineered to verify stability. Steep slopes beyond 3:1 ratio create landslide risks requiring geotechnical evaluation. Poor soils need engineered solutions. Adjacent structures within 25 feet face settlement risks requiring protective measures.

Permit Requirements and Regulations

Common Permit Triggers

Most building departments require permits when cut or fill depth exceeds 3-5 feet, total earthwork volume exceeds 50-100 cubic yards, grading area exceeds 2,000-5,000 square feet, work occurs within setback distances, or sites are in special zones like flood plains or wetlands.

Consequences of Unpermitted Work

Discovery of unpermitted grading creates serious problems. Building departments refuse new permits until violations are resolved. Stop-work orders halt activity with fines ranging $500-5,000+. Jurisdictions can compel restoration to original conditions if work violates environmental laws. Property sale disclosures require informing buyers, reducing value and complicating financing.

Frequently Asked Questions

What is the difference between cut and fill in grading?

Cut represents excavating or removing soil from higher areas to lower the ground elevation, while fill involves adding soil to raise low areas to the target grade. Cut material undergoes bulking (10-60% volume increase when loosened), while fill material experiences compaction (10-25% volume decrease when properly placed). The cost implications differ significantly: cut material costs $35-70 per yard to export, while fill costs $23-55 per yard to import. Projects requiring both operations pay combined costs unless grades are optimized to reuse cut as fill on-site.

How do you calculate cut and fill volumes?

Use the grid method by dividing your site into uniform cells (typically 10×10 feet), measuring existing and proposed elevations at each grid intersection, determining cut or fill depth at each point (existing minus proposed), multiplying each cell area by its depth, and summing all cut cells separately from fill cells. For linear projects like roads, use the cross-section method by creating perpendicular profiles every 20-50 feet, calculating cross-sectional area for each station, and finding volume between sections. Professional software uses triangulated irregular networks for maximum accuracy on complex terrain but requires investment in programs costing $200-2,000+.

What is soil bulking and why does it matter?

Soil bulking describes the volume increase when you excavate compacted in-place material. Natural soil under geological compaction becomes loose when excavated, introducing air voids. Sand bulks 10-15%, mixed soils bulk 15-25%, clay bulks 25-35%, and rock bulks 40-60%. Ten cubic yards of in-place clay becomes 12.5 to 13.5 cubic yards loose, requiring more trucking capacity and generating higher disposal fees. Forgetting bulking factors causes contractors to underestimate removal costs by 10-60% and order insufficient trucking capacity, delaying projects. Always apply bulking factors to cut calculations.

What is compaction and how does it affect fill volume?

Compaction removes air voids from loose fill through mechanical compression using rollers and compactors, increasing density and reducing volume while improving load-bearing capacity. Topsoil compacts 10-15%, common fill compacts 15-20%, and structural fill compacts 20-25% when achieving code-required 90-95% density. If you need 50 cubic yards compacted and order 50 yards without accounting for compaction, you end up with only 37.5-40 yards in place, leaving your grade 8-15 inches low. Calculate fills by dividing required compacted volume by the compaction fraction. Proper compaction requires 6-8 inch lifts, 4-6 passes with appropriate equipment, and verified density testing.

How do I balance cut and fill to reduce costs?

Adjust target grade elevation during design—raising proposed grade by 4-6 inches reduces cut requirements while increasing fill needs. For a 2,400 square foot pad with 40 yards excess cut, raising finished grade 4 inches reduces cut by approximately 30 cubic yards, saving $1,050-2,100. Redistribute material by stockpiling cut for later use as fill. Modify design elements: move pads toward natural high points, adjust alignment to follow contours, create berms consuming excess cut. Projects achieving 5% imbalance or less represent excellent balance, while exceeding 20% imbalance warrants serious grade revision or redesign.

How much does cut and fill grading cost?

Small projects like 50-foot driveways with 10 cubic yards cost $1,000-1,400 including excavator rental ($250-350), export fees ($400-700), and labor (4-6 hours at $75-100/hour). Medium projects such as 60×40-foot building pads requiring 50 yards cost $3,400-5,200 including equipment ($600-1,000), materials ($500-1,000), export ($200-400), labor (16-24 hours at $100-125/hour), testing ($200-400), and permits ($150-300). Large projects like 100×100-foot yard grading moving 120 yards run $8,900-14,900. Costs vary regionally with urban areas seeing 20-40% higher costs than rural regions.

Can I reuse cut material as fill on my project?

Yes, when cut material meets quality standards and you account for both bulking during excavation and compaction during placement. Clean fill dirt, sand, gravel, and well-graded mixed soils work excellently. However, organic-rich topsoil must not be used as structural fill because organics decompose over 2-5 years leaving voids causing settlement. Calculate reuse quantities accounting for both transformations: 50 cubic yards cut clay with 30% bulking produces 65 yards loose, which when used as structural fill compacting 22% yields 50.7 yards compacted. Cost savings from reusing cut as fill typically range $1,500-4,000.

What is the best calculation method for my project?

Use the grid method for flat to moderately sloped sites under 5,000 square feet, residential building pads and driveways on relatively even terrain, DIY projects where simplicity matters, and preliminary estimates where ±5-10% accuracy suffices. Use the cross-section method for linear projects like roads and driveways, sites with significant slopes, trenches and utility corridors, and where ±3-7% accuracy is needed. Use professional software (TIN method) for sites over 5,000 square feet with complex terrain, projects requiring engineering stamps, commercial work, and when ±1-3% accuracy is necessary.

Do I need a permit for grading my property?

Most jurisdictions require permits when cut or fill depth exceeds 3-5 feet, total earthwork volume exceeds 50-100 cubic yards, grading area exceeds 2,000-5,000 square feet, work occurs within setback distances from property lines, or sites are in special zones like flood plains or wetlands. Contact your local building department with project details. Permit costs typically range $100-500 with 2-6 week approval timelines. Consequences of unpermitted work include stop-work orders, fines of $500-5,000+, requirements to remove work and restore original grades, and property sale complications. Always check requirements before starting.

When should I hire a professional engineer for grading?

Engineering is required for large projects exceeding 100-150 cubic yards or 2,000 square feet, deep cuts or fills exceeding 6 feet, steep slopes beyond 3:1 ratio creating landslide risks, poor soils including expansive clays or soft organic soils, sites within 25 feet of existing structures, and all commercial or multi-family projects. Engineering review costs $1,500-3,000 for basic residential work but prevents failures costing tens of thousands. Many jurisdictions mandate engineering by code over certain thresholds. Verify local requirements early in planning rather than discovering them after starting work.

How many dump truck loads will my project need?

Standard tri-axle dump trucks carry 10-15 cubic yards depending on material density and local regulations. Divide your total volume by truck capacity: a 75-yard fill order requires 5-8 truckloads. For cut material, apply bulking factor first—50 cubic yards in-place clay bulking 30% becomes 65 yards loose requiring 4-7 trucks. Coordinate delivery scheduling since residential driveways typically accommodate only one truck at a time. Ask suppliers about minimum loads (often 10 yards) and delivery fees ($50-150 per load).

What equipment is needed for cut and fill work?

Small projects under 20 yards need mini excavators ($200-350/day) or skid steers, and walk-behind plate compactors ($75-150/day). Medium projects of 20-100 yards require mid-size excavators ($300-500/day), small bulldozers ($300-700/day), and vibratory rollers ($200-400/day). Large projects over 100 yards need full-size excavators, bulldozers, compaction rollers, and dump trucks ($150-350/day). Factor equipment into budgets: small projects add $300-600, medium projects $1,000-2,000, large projects $2,500-4,000+ for rental duration.

How long does a grading project take?

Small projects like driveways take 1-2 days including excavation, material hauling, and compaction. Medium projects such as building pads require 2-4 days for excavation, fill placement in lifts, compaction testing, and final grading. Large projects like yard grading span 5-10 days depending on complexity, weather, and testing requirements. Weather significantly impacts duration—wet conditions delay compaction work by days or weeks. Permit review adds 2-6 weeks before starting. Schedule conservatively: small projects allow 1 week total, medium projects 2-3 weeks, large projects 6-8 weeks from permit application to completion.

What are common mistakes in cut and fill calculations?

Forgetting soil volume changes leads to underestimating removal needs (bulking) or ordering insufficient fill (compaction). Not balancing cut and fill results in $2,000-6,000 unnecessary export/import costs easily avoided through grade adjustment. Using wrong calculation methods—grid on steep terrain or ignoring cross-sections for roads—creates ±15-25% errors. Skipping compaction causes 15-25% settlement and structural failure. Ignoring drainage creates water pooling and erosion. DIY on large complex projects creates safety risks and code violations. Skipping permits leads to stop-work orders and $500-5,000+ fines. Wrong material selection using topsoil as structural fill causes decomposition and settlement over 2-5 years.

How accurate are online cut and fill calculators?

Basic online calculators using simplified volume formulas provide ±10-15% accuracy, sufficient for preliminary budgeting on simple rectangular projects with uniform grades. Grid method calculators (like this one) achieve ±5-10% accuracy for moderate complexity sites when elevations are measured carefully. Cross-section method calculators reach ±3-7% accuracy for linear projects. Professional software using TIN methods delivers ±1-3% accuracy but requires significant investment. For most residential projects under 100 yards, ±5-10% accuracy suffices for planning and contractor bidding. Projects requiring precision (engineering stamps, large commercial work) need professional software and detailed survey data.