Point Load on Fill Dirt Calculator

Calculate stress distribution from concentrated loads on compacted fill. Analyze deck posts, equipment pads, and foundation points. Determine safety factors and when professional engineering is required.

Pro Fill Dirt Calculator

Accurate estimates for Yards, Tons, & Compaction

Results

How to Calculate for Point Load on Fill Dirt Calculator

The Formula

Simplified Boussinesq equation for vertical stress beneath point load. Load in pounds, depth in feet. Compare calculated stress to fill bearing capacity and verify safety factor exceeds 2.5 minimum.

Measure Accurately

Measure in feet. For depth, measure in inches and our tool handles the conversion (divide by 12).

Check Your Shape

Most calculate point-load-on-fill-dirt projects are rectangles. If irregular, break it into smaller shapes.

Add Compaction

Point loads create concentrated stress penetrating deep into fill and native soil. Inadequate analysis causes settlement, structural failure, and $10,000-$50,000 foundation repairs. Unlike theory-only resources, this calculator provides practical guidance for DIY screening and knowing when to hire engineers.

What Is a Point Load and Why It Matters

Point Load Definition

A point load represents a concentrated force acting on a small contact area, typically less than one square foot. Common examples include deck posts bearing on 6×6 bases (36 square inches), equipment supported on small feet (often 4-9 square inches), and column footings concentrating building weight onto compact areas. This concentration creates dramatically different stress patterns compared to distributed loads like concrete slabs that spread weight evenly.

Why Point Loads Challenge Fill Dirt

Compacted fill presents unique challenges for point load support. Fill compaction inevitably varies throughout depth despite best efforts—some lifts achieve 98% density while others barely reach 92%. Point load stress penetrates deep into fill and underlying native soil. At 3 feet below a point load, stress typically reduces by 70-75% but affects soil in a 6-8 foot diameter circle. Settlement risk amplifies dramatically on fills compared to natural deposits.

Understanding Stress Distribution in Fill Dirt

How Point Loads Spread Through Soil

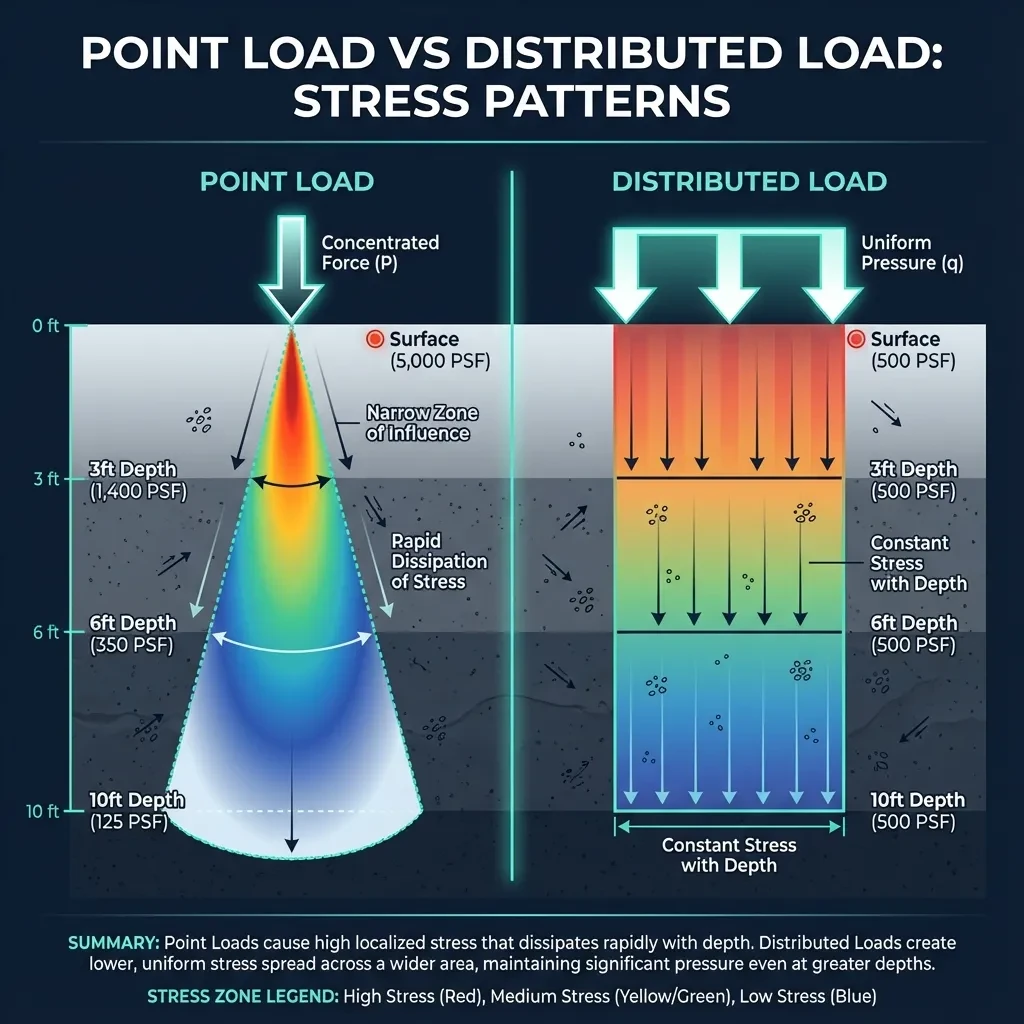

When a concentrated load presses against fill surface, 100% of that force initially concentrates on the small contact area. However, the soil mass "fans out" the load in a cone-shaped pattern, progressively distributing force across larger soil volumes as depth increases. At 3 feet below a point load, stress typically reduces to 25-30% of surface intensity but now affects a circular zone 5-7 feet in diameter.

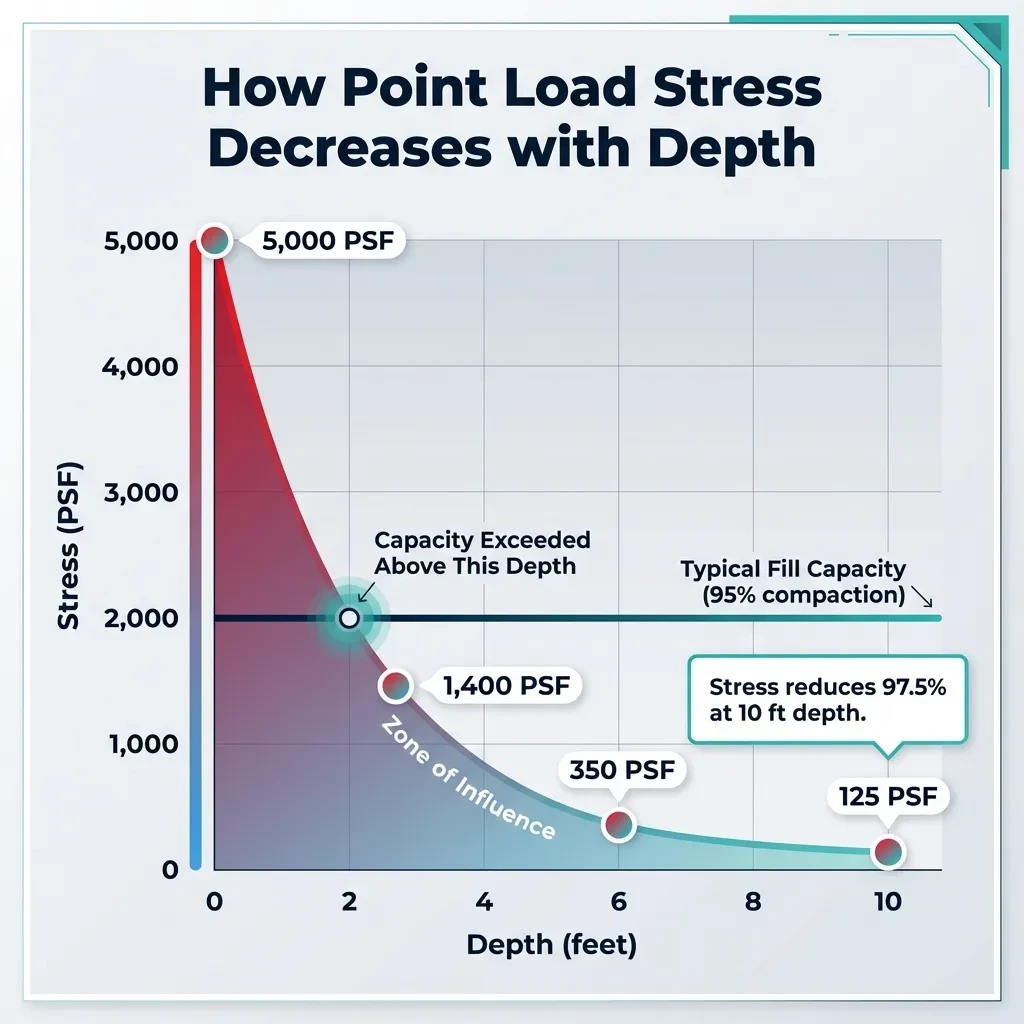

Boussinesq's Equation (Simplified)

French mathematician Joseph Boussinesq developed stress distribution theory in 1885. The simplified formula for vertical stress directly beneath a point load is: Stress = (Load / Depth²) × Influence Factor. For most residential calculations checking stress directly below posts, using 0.48 as the influence factor provides conservative results. Example: A 5,000-pound deck post at 3 feet depth ≈ 0.48 × (5,000/9) = 267 PSF.

Bearing Capacity of Compacted Fill Dirt

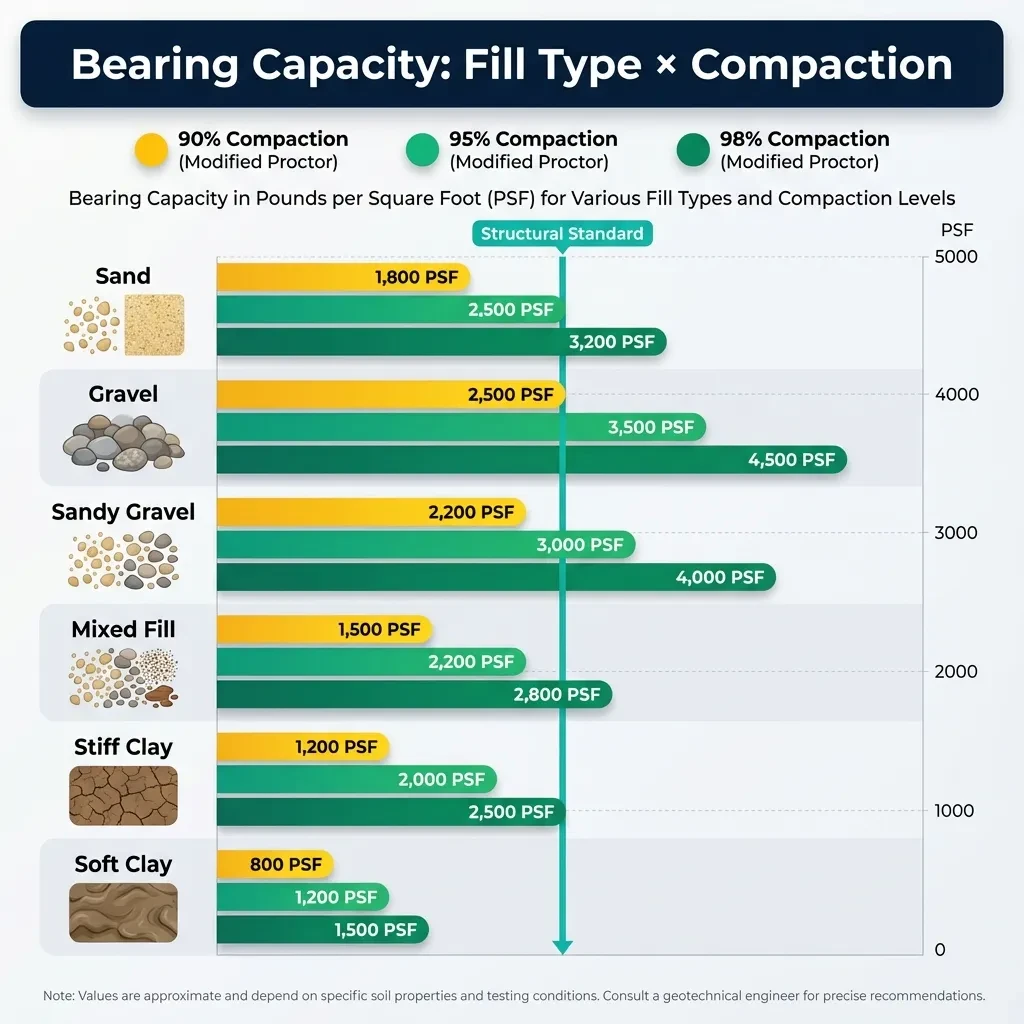

Bearing Capacity by Fill Type

Clean sand compacted to 95% Standard Proctor typically provides 2,000-2,500 PSF allowable bearing capacity. Gravel and sandy gravel mixes achieve superior capacity: 3,000-3,500 PSF at 95%, reaching 4,000-4,500 PSF at 98%. Clay fills perform poorly: soft clays rate only 800-1,200 PSF even at 90-95% compaction. Mixed fills containing sand, silt, and clay particles together typically rate 1,500-2,200 PSF at 95% compaction.

Why Compaction Percentage Matters

The difference between 88% and 95% compaction translates to 35-45% higher bearing capacity and 60-70% less settlement. Spending $75-150 per compaction test prevents $5,000-20,000 foundation repair bills from settlement or failure. Achieving 98% compaction costs only 10-15% more than 95% but delivers 20-30% more capacity.

Common Residential Point Loads

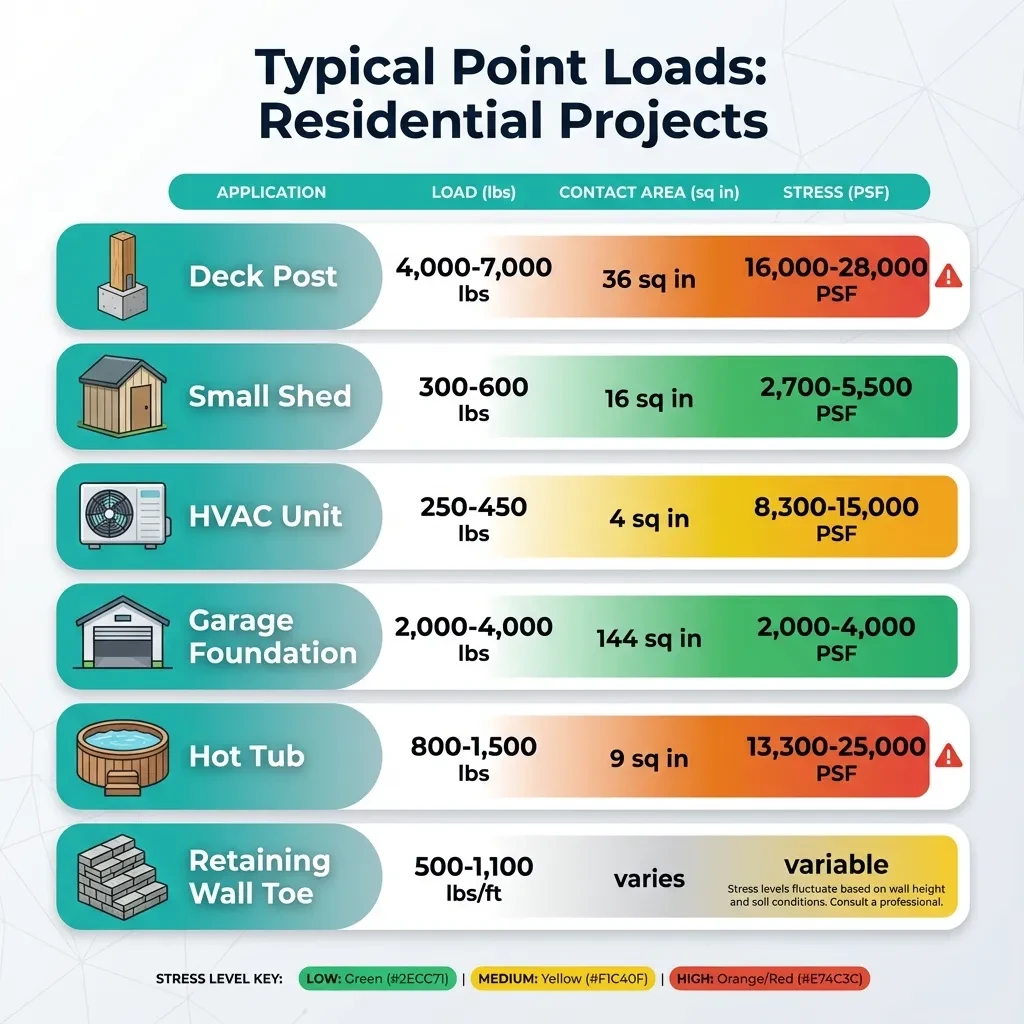

Typical Applications

Deck Posts: 4,000-7,000 lbs typical (creates 16,000-28,000 PSF surface stress on 6×6 post). Small Sheds: 300-600 lbs per corner post. Equipment Pads (HVAC): 250-450 lbs creating 8,000-15,000 PSF on small feet. Garage Foundation: 2,000-4,000 lbs at corners. Hot Tub Supports: 800-1,500 lbs per support point creating 13,000-25,000 PSF.

Safety Factor Requirements

Safety Factor (SF) = Allowable Bearing Capacity ÷ Applied Stress at depth. Minimum accepted safety factors: 2.5 for residential structures, 3.0 for settlement-sensitive applications, 3.5-4.0 for fills with limited testing or hot tubs. Safety factors below 2.5 require design modifications—larger footings, improved compaction, or professional engineering.

Recommended Safety Factors

- Residential decks/sheds: Minimum 2.5, Recommended 3.0-3.5

- Equipment pads (static): Minimum 2.5, Recommended 3.0

- Hot tubs/pools: Minimum 3.0, Recommended 3.5-4.0

- Garage/workshop floors: Minimum 2.5, Recommended 3.0

- Commercial structures: Minimum 3.0, Recommended 4.0+

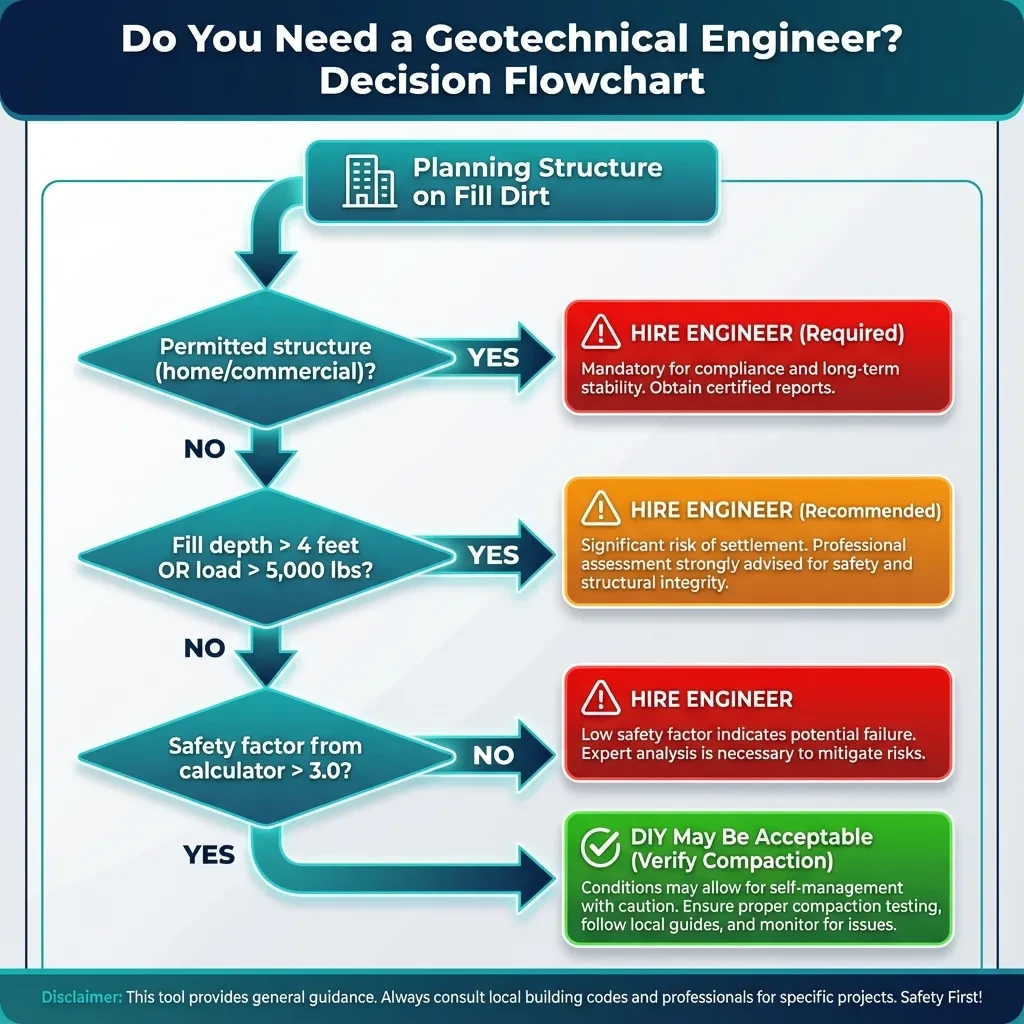

When to Hire a Geotechnical Engineer

DIY-Safe Scenarios

Small sheds on less than 2 feet fill (under 200 sq ft footprint), deck posts on verified 95%+ compacted fill under 3 feet deep, equipment pads (HVAC, generators) on thin fill, calculated safety factor exceeding 3.5, and no settlement-sensitive adjacent structures.

Engineering Required

Residential home foundations on any fill, commercial buildings, fill depth over 6 feet for any structure, retaining walls over 4 feet height, poor native soil below fill (soft clay, peat), any project requiring building permit, safety factor under 2.5 from calculator, adjacent structures within 1.5× fill depth.

Typical Engineering Costs

- Basic soils report (residential): $1,500-$3,500

- Comprehensive geotechnical investigation: $3,000-$8,000

- Plate load testing: $500-$1,200 per test

- Compaction testing (per test): $75-$150

- Engineer consultation (hourly): $150-$300/hour

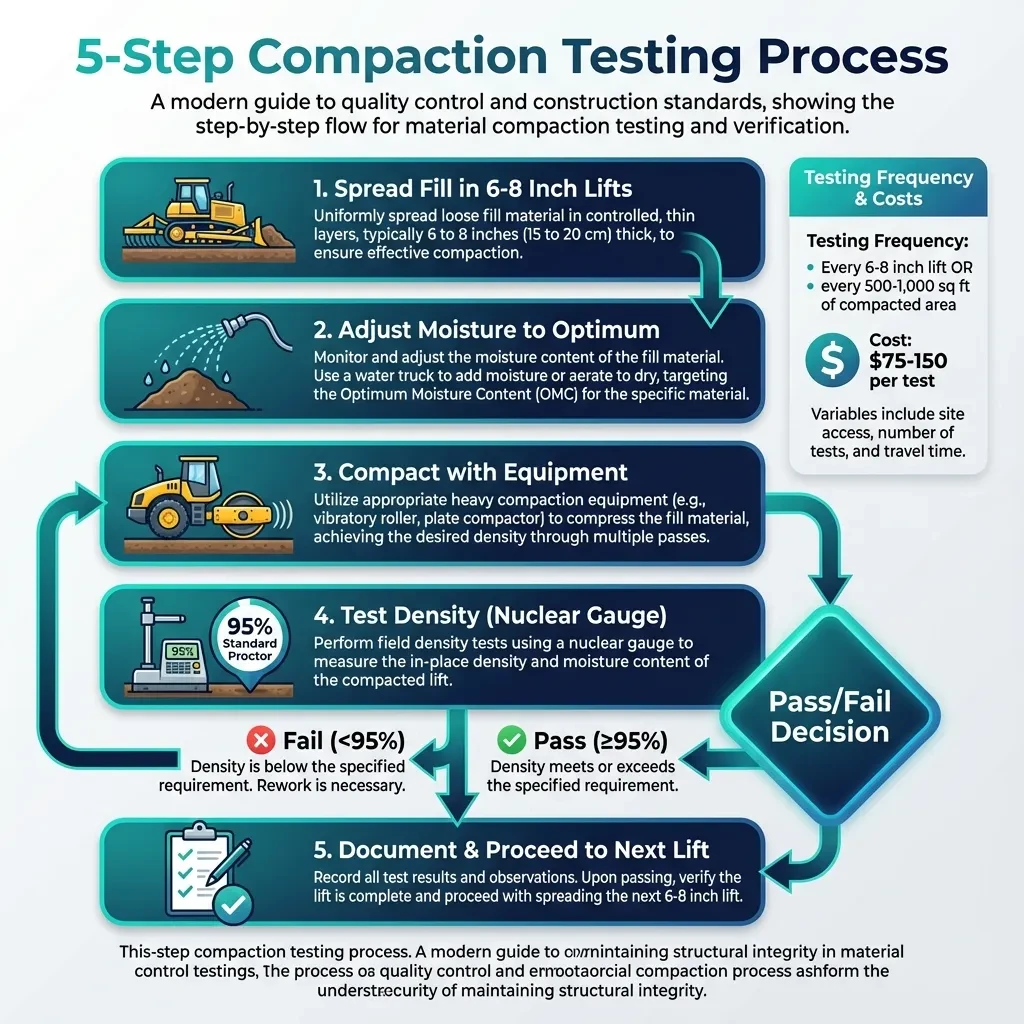

Compaction Requirements for Point Load Support

Minimum Standards

Minimum 95% Standard Proctor compaction required for structural fills supporting point loads. This balances achievable field performance against engineering requirements. Critical applications benefit from 98% compaction, which delivers 20-30% more capacity and 50-70% less settlement than 95%. Below 90% compaction, fills become unpredictable with high settlement risk.

Testing Frequency

Test every 6-8 inch lift OR every 500-1,000 square feet, whichever occurs more often. A 1,000 square foot area filled 3 feet deep requires 4-8 tests minimum. Per-test cost: $75-$150. Compare to repair costs if settlement occurs: $5,000-$20,000+.

Common Mistakes

Ignoring Fill Depth

Must check stress through entire fill to native soil below

Assuming All Fill Is Equal

Sandy fill (3,000 PSF) vs clay (1,500 PSF) = 2× difference

Skipping Compaction Verification

Visual inspection cannot detect 85% vs 95% compaction

Using Bearing Capacity Alone

Settlement still occurs even with adequate bearing

Ignoring Native Soil Below

Weak native soil limits capacity regardless of good fill

Not Accounting for Multiple Loads

Adjacent posts create overlapping stress zones

DIY on Deep or Critical Fills

Calculators are screening tools, not engineering design

Trusting Old Fill Without Testing

Unknown compaction, possible settlement already occurred

Explore More Calculators

Planning additional fill dirt projects? DirtMasters offers specialized calculators for every application:

- Fill Dirt Calculator (Homepage) - General purpose cubic yard calculator

- All Calculators - Browse our complete collection

- House Pad Fill Dirt Calculator - Building pad preparation

- Compacted Fill Dirt Calculator - General compacted fill

Frequently Asked Questions

What is the difference between a point load and a distributed load on fill dirt?

A point load concentrates force on a small area (typically under 1 square foot), such as a post, column, or equipment foot, creating high surface stress that penetrates deep into soil in a cone pattern. Distributed loads spread weight evenly across large areas like slabs or continuous footings, creating lower, more uniform stress. Point loads require deeper stress analysis because they affect soil zones 5-10+ feet in diameter at moderate depths.

How deep does stress from a point load penetrate into compacted fill?

Point load stress penetrates approximately 1.5-2.0 times the depth for significant influence. Stress typically reduces to 25-30% of surface stress at 3 feet, 7-10% at 6 feet, and 2-3% at 10 feet. For fills over native soil, you must calculate stress through entire fill depth plus 1-2 times fill thickness into underlying native material.

What compaction percentage is required for fill dirt to support point loads safely?

Minimum 95% Standard Proctor density required for structural fills supporting point loads. This balances field achievability against engineering performance. Critical or heavy loads benefit from 98% compaction. Below 90% compaction, fills become unpredictable with high settlement risk.

How do I calculate the safety factor for a point load on fill dirt?

Safety Factor equals Allowable Bearing Capacity divided by Applied Stress at depth. Calculate stress using Boussinesq methods, look up allowable capacity for fill type and compaction, then divide. Minimum SF = 2.5 for residential, preferably 3.0-3.5.

Do I need a geotechnical engineer for a deck built on compacted fill?

For small decks under 200 sq ft on shallow verified 95%+ fill with SF over 3.5, DIY may be acceptable. Engineering recommended for decks over 300 sq ft, fills deeper than 4 feet, hot tubs, unknown compaction, poor native soil, or when permits required. Cost $1,500-3,000 prevents $5,000-15,000 settlement damage.

What is Boussinesq's equation and why does it matter for fill dirt?

Boussinesq's equation calculates vertical stress at any point in soil beneath a surface point load. Developed in 1885, it predicts how concentrated surface stress dissipates with depth, enabling verification that stress at critical depths remains within safe capacity limits.

How much does testing compacted fill cost and is it really necessary?

Compaction testing costs $75-150 per test. Typical project requires 3-8 tests ($300-900 total). Testing is absolutely necessary because visual inspection cannot distinguish 85% from 96% compaction, yet this affects capacity by 30-40% and settlement by 60-80%.

Can old fill dirt that's been in place for years support point loads?

Possibly, but never assume—always test before relying on existing fill. Unknowns create risk: original compaction unclear, material composition uncertain, previous loading might have caused settlement. Test at proposed load locations and verify both fill and underlying soil capacity.

What happens if the native soil below my fill is weak?

Point load stress penetrates through fill into native soil. If native capacity falls below applied stress, failure occurs at the weak layer regardless of excellent fill above. Solutions include removing weak soil, deep foundations extending to competent bearing, or reducing loads through larger footings.

How do multiple point loads near each other affect stress in fill dirt?

Multiple loads spaced closer than 2-3 times depth create overlapping stress zones with combined peaks 20-45% higher than individual calculations. Use conservative combined loading assumptions or geotechnical software for closely-spaced loads.

Is settlement or bearing capacity more important for structures on fill?

Both matter equally, but settlement often governs design. Fills might safely carry loads without shear failure while settling 1-2 inches, damaging structures. Professional engineers evaluate both simultaneously, ensuring designs prevent failure AND limit settlement.

What's the maximum fill depth I can use without engineering for a residential project?

For permitted structures, engineering legally required regardless of depth. For non-permitted minor structures, depths under 3 feet with verified 95%+ compaction and SF over 3.5 may be DIY-suitable. Beyond 4 feet, professional analysis mandatory.

How does moisture content in fill dirt affect its load-bearing capacity?

Each soil has optimum moisture content (8-15% for sand, 12-20% for clay) where compaction achieves maximum density. Too dry or wet prevents proper compaction. After placement, saturated fills lose 10-25% capacity. Drainage prevents saturation and preserves capacity.

Can I build a garage or shed on fill dirt without removing it?

Yes, if fill is structural-grade, compacted to 95%+ with testing, uniform thickness, and adequate capacity. Sheds under 200 sq ft on 2-3 feet tested fill may proceed with calculator verification. Garages need engineering. Removal necessary if fill contains organics, compaction unknown, depth exceeds 6 feet, or native soil very soft.

Can I use the same bearing capacity for fill dirt as natural soil?

No—bearing capacity varies dramatically. Well-compacted gravel fill achieves 3,000-3,500 PSF, exceeding natural clay at 1,500-2,500 PSF. Poor fill below 90% might rate only 800-1,500 PSF. Compacted fill also exhibits 2-4 times more settlement than natural soil despite higher bearing.